Omega Splinting Material

Moderate - Maximum Resistance to Stretch

Conformability, moderate RTS, and 100% memory combine for a versatile splinting material.

Resistance to Stretch

Moderate resistance to stretch.

Moderate to aggressive handling is tolerated.

Drape

Moderate to maximum drape to create a close conforming fit.

Provides excellent reproduction of detail.

Memory

100% memory, ideal for serial splinting.

Always recovers its original cut shape and size when reheated.

Rigidity

Moderate to maximum rigidity.

Bonding

Uncoated material. Provides a very sticky surface when warm and bonds without the need for solvents.

Sticks easily to itself. Use as bonding agent to attach outriggers or other accessories to splint.

Use as a bonding agent to attach outriggers or other accessories to a splint or a permanent bond, apply dry heat to the surface until shiny and attach accessories directly to the material.

Wet bonds can be released in warm water if necessary.

For easier handling, add liquid soap to water and keep thermoplastic damp while molding.

Handling instructions are included.

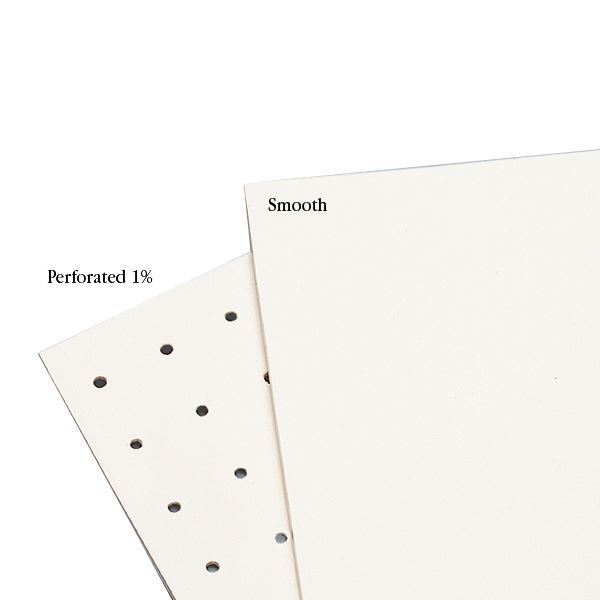

Surface Finish

Finished splints have a smooth, glossy surface.

Fingerprints and other surface marks disappear as the material cools. Makes professional looking orthosis.

When cut while warm, Omega Max forms smooth, sealed edges.

Applications

Use 3.2mm Omega Max for hand or wrist splints back supports, anti-spasticity splints, lower extremity positioning splints, serial static splints and bases for dynamic splints.

Use 2.4mm Omega Max for lightweight hand or wrist splints. Because of its superior rigidity, 1.6mm Omega Max can be used for dynamic splint bases.

Pediatric splints made from the 3/32" thickness have excellent conformability and will hold against strong hypertonicity.

Working Time

Allows approximately three minutes to form and harden after softening in 60° C to 66° C water.

Fastest setup time, ideal for busy clinics and patients who benefit from less handling time